Dudley Kingsnorth of Industrial Minerals Company of Australia (IMCOA) answered the following quetions via written response in March 2008.

Clint Cox: Please describe the history of your involvement with the Rare Earth industry.

Dudley Kingsnorth: In 1990 I was head-hunted by Ashton Mining Ltd (who jointly owned the Argyle Diamond Mine with Rio at the time and have subsequently been taken over by Rio) to manage the Mt Weld Rare Earths Project; which I did until 2000. Since then I have maintained an interest in the rare earths industry by maintaining contact with the people I met during that period when the rare earths industry went through a roller coast ride as it adjusted to the entry and subsequent domination by China. I have written the last three editions of Roskill’s “The Economics of Rare Earths and Yttrium” (2001, 2004 and 2007) which has enabled me to remain abreast of developments. Currently, I am an independent rare earths consultant which keeps me abreast of current and future developments through the companies and people with whom I work and consult.

Cox: Please talk about the most notable changes in the history of the industry, with particular reference to China.

Kingsnorth: The most notable changes in the industry over the past few years may be considered in two parts:

1. The growing dominance of China over the past twenty to thirty years. This commenced in the 1980s with the separation of the rare earths as a by-product of the Bayan Obo Iron Ore Mine in Inner Mongolia. Today 40-50% of the world’s rare earths are sourced from this mine; constituting over 60% of the global supply of light rare earths. Then in the 1990s ionic clays became the dominant source of heavy rare earths; such that today this is the source of over 85% of the global supply of heavy rare earths.

2. The problem of ‘balance’ – in which the ratio of the rare earths mined/processed does not comply with the ratio of demand – has undergone several changes. In the 1950s and 1960s europium, for use in the phosphors in the ‘new’ color TVs, was the driver of the industry, with the Mountain Pass in the USA the major supplier. In the 1980s and early 1990s the demand for cerium for TV and computer monitors, where it is used to polish the screens and as a decolorizer, drove the demand; which, in turn helped the Bayan Obo Mine, with its high cerium content, to become the major force in global rare earths supply. Today, it is the rapidly increasing consumption of neodymium, praseodymium and dysprosium in the production of rare earth magnets that is driving demand. Tomorrow it could well be the consumption of europium, terbium and yttrium in the manufacture of phosphors that could dictate the patterns and sources of rare earths production.

Cox: How intentional are the Chinese about their long term REE plans? Are REEs a national or regional priority in China?

Kingsnorth: It is my belief that the Chinese authorities at all levels are utilizing their rich rare earths endowment, not only their resources but their technology and expertise, as a key instrument in the achievement of their goal to find jobs for the millions of people that will move from an agricultural environment to and urban one between now and 2020. Due to their unique properties and their use in minor quantities rare earths provide significant leverage in the creation of jobs in the manufacture of electronic, automotive and catalytic items. Accordingly, I do not believe that China’s motives are ideologically or directly financially founded. This is best illustrated by the fact that the authorities at all levels are putting an increasing range of caveats with respect to ‘adding value’ on the current and future development of rare earth resources. Several Provinces, through the controlling interest they hold in rare earth enterprises, are now making value adding manufacture, such as LCDs and electric motors, a pre-condition for continued access to their rare earth resources.

Cox: In the larger context of their manufacturing base, how aware are the Chinese of REE?

Kingsnorth: They are keenly aware of their strategic importance and are using that to expand their manufacturing base.

Cox: Recently, there have reports that the Chinese REE resources are finite, as a consequence of which they are limiting supply to an extent that the West may be starved of REEs within 5 years. Can you comment?

Kingsnorth: First I would comment that the Chinese rare earths industry currently supplies in excess of 95% of global demand for rare earths; which in itself raises issues of sovereign risk. There appears to be some general consensus amongst the Western major manufacturers of LCDs, mobile phones, computers, electric motors, etc. that there is a reluctance to place more than 60-70% of their manufacturing capability within China. This indicates that subject to the normal caveat of ‘reasonable pricing’ these Western companies would support non-Chinese projects in order to achieve this goal.

Over the past two years several Chinese officials have raised issues about supply from Bayan Obo (where there could be supply constraints in the medium term associated with the shift to a new mining area where the rare earths concentration is lower and the time required to develop suitable methods of recovering the million of tons of rare earths contained within the tailings ponds) and, more importantly, the supply of heavy rare earths from the ionic clays of Southern China which are finite and cause significant environmental damage during their processing.

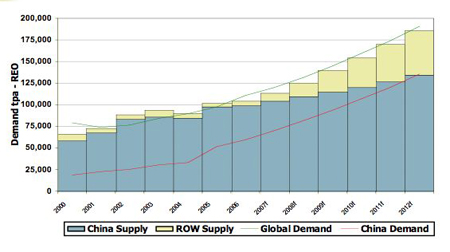

It is the combination of sovereign risk and the uncertainties associated with the supply that are creating the opportunities for non-Chinese rare earth projects. Based upon the comments made by the Chinese officials and a conservative forecast growth in demand of 8-11%pa there could be a potential shortfall of 30-40,000tpa in 2012, which would need to be filled by the current potential but un-committed non-Chinese rare earth projects, as shown in the figure below:

I suppose, the next question is would China starve the West of rare earths and allow prices to increase to record levels if these projects did not come on-stream? The simple answer is no; the Chinese authorities are pragmatists and would not allow this to happen for the following reasons:

1. If prices were to rise to really high levels (in historical terms the current prices are not high in real terms) then the temptation for illegal mining and processing to re-commence in China would be almost unstoppable, leading to chaos, environmental problems and a sharp fall in prices. The authorities wish to remain in control.

2. High prices would drive more dollars to the search for substitutes; particularly in Japan.

3. China could be subject to action by the WTO.

In summary, I believe that China will ensure that there are adequate supplies, albeit at higher although not outrageous prices, but the real price would be the shift of more manufacturing to China.

So, as I noted at a recent conference the time has come for the would be non-Chinese rare earth projects to step up to the plate and deliver on their promises to meet this potential shortfall!

Cox: Please describe the differences between the US, Japan and Europe’s concept of REEs:

Kingsnorth: Very few people within the USA appear to understand the role that rare earths play in our society today i.e. put simply, the fact that the most efficient electric motors contain rare earth magnets is of little relevance when the purchasing decision is made on the basis of price.

In Japan:

“Oil is the blood of industry,

Steel is the rice of industry

Rare earths are the vitamins of industry.”

Outside China, Japan is the major investor in rare earths application R&D.

In Europe they are aware of the importance of rare earths, but lack the resources to address the lack of diversity of supply. Nevertheless, there are R&D programs associated with rare earth applications.

Cox: How important are India and Russia to the REE industry?

Kingsnorth: They do have the potential to play a key role in meeting the potential shortfall identified above. However, past performance suggests that their impact will be minimal.

Cox: Turning to China; please comment on the relationship between end users and that country.

Kingsnorth: For many non-Chinese users it is not a preference but a question of ‘no choice’ of supply. Although there have been significant improvements in the reliability of supply from China, many companies still have some way to go to meet Western standards of quality control. Nevertheless, it needs to be acknowledged that it is an issue of which the industry is well aware and is committed to continuous education/improvement.

Cox: What are the 3 greatest risks for the REE sector?

Kingsnorth:

• Overpricing, due to Chinese supply constraints and taxes, will foster substitution.

• Poor environmental management in China could lead to a boycott of products that are not produced by ‘green’ companies.

• A break-out in supply in China due to high prices which will drive down prices in the medium term which will force cut-backs in research and quality control.

Cox: What are the chances of making a brand new discovery that changes the market?

Kingsnorth:

• In the next 5 years minimal, possibly in 5-10 years.

• Developing a commercial process is the key, for example it has taken over 15 years for Lynas and its predecessors to develop a commercial extraction process for Mt Weld.

Cox: Will end users partner with exploration companies to expedite the development of alternative sources of rare earths?

Kingsnorth: Not directly, but through supply chain management with other users.

Cox: Describe the current relationship between end users and REE exploration companies.

Kingsnorth: The major end-users are coming to realize that they need to have a full understanding of their supply source – right to the mine site. So, they are becoming more ‘interested’, but for most the idea of contracting at the top of the supply chain is not an option. However, they do have an ‘interest’ in how their suppliers source their raw materials, such that it could impact on their purchasing decisions; an ‘interest’ that I see increasing as China increases its grip on the market. In other words, I foresee a greater interest in totally transparent supply chains from mine to customer on the part of the major rare earth consuming manufacturers

Cox: Will REE exploration companies outside China be able to compete? What will it take for them to be profitable?

Kingsnorth: At current prices non-Chinese projects appear to be profitable from the feasibility study results published to date. So it appears that they will be profitable, but will probably not be able achieve the margins of their counterparts in China.

As long as the current export tax and quota system remains in place, which effectively distorts the market, and they are supported by the non-Chinese consumers then the non-Chinese companies will be able to survive.

Cox: How would you describe the present state of the rare earth market?

Kingsnorth: “We live in interesting times”. The key to a dynamic future for the rare earths industry is the successful development of non-Chinese rare earth suppliers, who will give the confidence required by industry to continue to research and use this unique group of elements

Cox: What do you think is the most common misperception about rare earths?

Kingsnorth: Rare earths are the play things of university research departments. The industry as a whole has a responsibility to educate the general public about the unique role that rare earths play in our society today.

Cox: Will the Japanese stockpile REE?

Kingsnorth: The Japanese have always taken the opportunity to stockpile strategic materials when the conditions are appropriate i.e. as long as the purchases do not trigger major price increases. From the trade statistics it appears that Japan has been stockpiling rare earths over the past 2-3 years.

Cox: Will the US stockpile REE?

Kingsnorth: Not that I am an American citizen, it is a question that I suggest you raise with your local Member of Congress or Senator. As you are aware over the last few years the US Government has made a conscious decision to sell down the stocks of strategic materials. However, more recently the US Department of Defense appears to be putting ‘USA made’ policies in place, which may lead to a rebirth of the REE industry in the USA.

Cox: What are the 4 most important things to know about each REE?

Kingsnorth:

- The current and future (potential) applications.

- Growth of each application.

- Propensity for substitution.

- The balance between supply and demand for that REE.

Cox: Could you name the three people who have most influenced your association with the rare earths industry?

Kingsnorth:

• Barry Kilbourne (dec’d) of Molycorp who devoted his career to promoting a better understanding of rare earths. “Cerium – A Guide to its Role in Chemical Technology” and “A Lanthanide Lanthology”, both of which are well regarded references today are testament to his dedication.

• Peter Gundy, the founder of Neo Material Technologies (formerly AMR Technologies) whose commitment to the industry and the wellbeing of the people and communities within which the company works in China has raised the general standards of the industry as a whole.

• Rob Duncan of Lynas Corporation whose dedication to the understanding of the complex orebody at Mt Weld has played a key role in its progression from exploration play to producer (in 2009).